Monday, April 19, 2010

Alex Spring's Oval

After getting the car ready for it's first outing at last years VW Action in September at Santa Pod . Alex has been waiting for decent weather and some spare time this year , to come down and attend to the last few tweeks on the car . His aim is to give the car a few runs up the strip at next weekends " Big Bang " VW event , at the Santa Pod Raceway drag strip .

He came down early Sunday morning , and while he removed the engine , to fit one of the new Viton crankshaft oil seals I have , I set about raising and leveling the rear suspension ( it was slightly low , and down a little one side ) . I also modified and fitted T2 Bay window rubber rear bump stops , onto T1 mounting brackets , modified to fit an Oval . This is to help stop the car squatting under acceleration .

I also fitted longer rear wheel studs , as the ones fitted only allowed the wheel nuts to go on a few turns , not really satisfactory .

It was a glorious sunny Sunday , we had a good laugh , as well as getting the car sorted . Richard Beck ( JG54 member , Texas Brown Zwitter ) popped down to pick up a couple of parts , and Dominic Hill ( JG54 Prospect , 65 Beetle ) , came along in the afternoon to lend a hand and make it light work .

Neal Anderson's 56

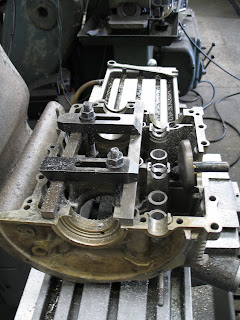

Neal came down at the weekend , to take the engine out of his car , to fit his racing set-up , ready for next weekends " Big Bang " VW event at Santa Pod Raceway drag strip . Now that he runs the car on slicks at the track , before the event , we drop the engine out , fit a slightly stronger pressure plate , and swap the gearbox yoke mount ( Modified BugPack with Grey VW rubbers for the street ) , to a solid BugPack mount , for the strip . We also fit ally blocks to the intermediate mount , as apposed to the rubber ones used for street use .

I also wanted to check the valve springs out , as they have been on the car for a few years now , and I thought they might be worth checking . Neal had commented that the car didn't " pull " at the top end like it used to . I checked the spring tension , and at the lift he runs with a Web-Cam 86c , with Pauter roller rockers , 0.546" lift . A fresh Scat VW Diameter dual spring came out at about 280 pounds at 0.550" lift , whereas Neal's were down to 235 pounds , quite a drop . We are going to try the new VW650 springs from CB Performance , and see how this goes , and if it makes any improvement on his 12.9 sec PB .

Ivan's Beam ( White 67 )

Alex Taylor ( www.defcon-3.co.uk ) came to visit on Friday afternoon . He brought with him the original beam out of Ivan's White 67 . The car has been running a Puma adjustable beam , but the trailing arms are too tight in the trailing arm bearings ( a common problem ) , resulting in a choppy ride . Also , the car runs drop spindles , and the slight track increase you get with drop spindles means that when the original beam is refitted , and the suspension has travel ( which is doesn't at the moment , due to the excessively stiff suspension , caused by the tight trailing arms ) , the tyres will rub the wings ( As did Ivan's beige 67 , before Alex narrowed the beam to correct the drop spindle track increase ). Alex has narrowed the 27,000 mile beam 20 mm a side , to correct the drop spindle offset . He also fitted Sway-Away adjusters . He has re-painted the beam in 2K black and 2K clear lacquer . It sure looks beautiful

Tuesday, April 13, 2010

Gary Richards' 67

After successfully bushing Ivan's lifter bores yesterday , today it was Gary's engine case turn . The engine for Gary's 67 looker , is a 2165 cc 48IDA Ripper . The engine was in another car that Gary had bought from fellow Grunherz club member Tim " Coldplay " Cooper . Gary sold that car on , but kept the engine . And he bought the 67 ( pic's further down on the blog ) that he has been working on , from Alex Taylor . The 2165 has got about 50,000 miles on it now , with a couple of top end freshen ups over this time , and a new cam and lifters a few thousand miles ago ( FK10 & CB 30mm lightweight lifters ) .

Before fitting into his new 67 , Gary asked if we could go right through the engine to make sure it was as good as it can be . The valve guides were a little worn , these are being fitted with Cosworth inserts , and having a valve seat job by Jim at Stateside Tuning , on his brand new Serdi valve seat machine .

Three of the lifter bores were a little worn on Gary's case , so we decided to bush the case while we were set up to do Ivan's .

We pushed the lifter sleeves a little way in to start with the Bridgeport mill head , to start them off straight , then they were tapped home with a specially made to fit the sleeve drift . A little bearing fit Loctite was used to guarantee no movement of the bushes once fitted .

Monday, April 12, 2010

Dominc Hill's 65

Dom's been collecting bits and pieces for his 65 while the shell is being painted . The shell goes into primer tomorrow , and paint shortly after that .

Dom has spent plenty of evenings working on his stuff here . The 1776 cc engine that was in his car , has been freshened up and sold on . He has purchased a 2007 cc engine from a friend of mine , James . The engine has been stored for the last 10 years , since James moved to Germany . Dom has stripped the engine down completely for inspection . the engine had done about 1500 miles , and just like Ivan's engine , which was built about the same time , the cam is on it's way out , and the lifters were pitted .

So Dom ordered a new FK8 cam , new piston rings , and from CB Performance , some of their excellent 30 mm 2 piece lightweight cam followers and a set of their new VW650 valve springs . The springs are a new product from CB , and are the nicest spring I have ever seen , beautifully finished . So for the next couple of weeks , Dom will be putting the engine back together with my guidance .

Dom has also had the engine case vapor blasted , as it was very grubby , having been sat around for 10 years .

Dom also picked up a mint set of 48 IDA's , at The Volksworld Show , so now owns his first set of IDA's !

Ivan's 67 ( White One )

Today we are seeing if Ivan's 2007cc engine case , that has worn lifter bores ( one badly ) , is repairable by fitting aluminium sleeves . The sleeves are 24mm OD , the lifter bore that was badly worn was reamed out gradually , to see how bad the damage was . We were hoping that the bore would clean up before the 24mm size was reached .

Luckily the bore just about cleaned up , there was a tiny mark left at the bottom of the lifter bore , but it was so minimal that we decided to fit the sleeve and see how it went . On the advice of John Maher , who built this engine 11 years ago , he advised machining the rest of the lifter sleeves down to 22mm , so as to leave as much of the original lifter boss intact as possible . Ron , my engineer friend , reamed out the lifter bores to 0.02 mm interference fit ( As per instructions ) , with the machined down lifter bushes . We heated the case with two electric fan heaters and put the bushes in the freezer . Ron made a drift that sat inside the lifter bushes , so they could be pushed a little way in to start , with the Bridgeport mill , then hammered home . To finish the job , Ron machined a chamfer at the top of the sleeve , to allow the lifter to sit flush with the bush . The porting sticks that I use , just happened to be exactly the right size to run up and down the fitted sleeve , to leave a nice even honed finish .